Reducing our dependence on water in the manufacture of Denim has been the mission of JEANOLOGIA, Spain since day one.

Jeanologia, Spain are the pioneer makers of denim and jeans processing equipment which use significantly less water to process both denim and jeans. With vision, perseverance and passion Enrique Silla the founder owner is transforming our thirsty and dirty denim and jeans industry.

the G2 Dynamic ozone fabric processing equipment uses only one cold bath of water to finish the fabric compared to many gallons in a normal process. It uses no chemicals thus eliminating the need for caustic treatment. The consumption of water per metre of fabric is insignificant. There is no harmful discharge and no thermal energy is required. It also has added performance benefits for the denim itself.

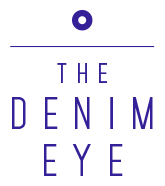

Using denim finished by this method in a jean which is further finished with the Jenologia Lazer garmenting equipment we can achieve the most sustainable jean in the World today.

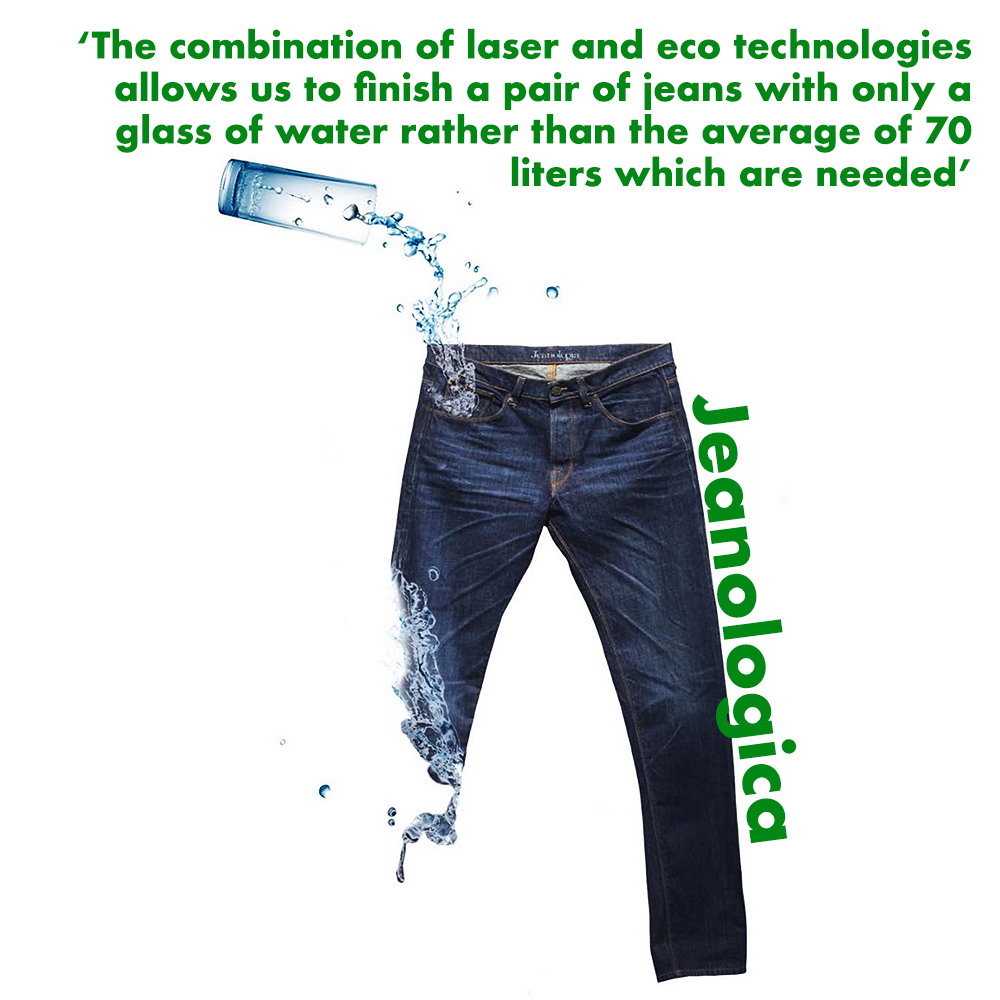

The above illustration demonstrates the saving of water, energy and chemicals achieved by using jeanologia’s equipment. One denim manufacturer has branded their product “THIRST FREE” Denim!

Water, our most precious element instead of being used in the growing of cotton could be harnessed to alleviate drought and starvation of millions. Above are the shocking statistics of just how much irrigation water is needed in cotton growing.

Denim and jeans manufacture uses approximately 8000 litres of water to make just one pair of jeans!! Shocking but true. Including thirsty cotton growing, indigo blue dyeing, denim finishing, jeans laundry washing many times per jean it is easy now to see how this quantity can be achieved.

The water from denim dyeing is blue and indigo has no affinity with cotton so the denim has to be washed many times to eliminate the excess surface indigo, resulting in blue water which must be cleaned and free from chemicals before returning to nature.

It is obvious what happens to the earth without water.

We all know what happens to the earth without water. It is desert.

The ground becomes parched and cracked. The surface becomes impossible to cultivate being starved of nutrients. We all must reduce our water use not just the denim and jeans makers. We must learn to use less. Later this month i share ways of finishing jeans that will use little or no water in the manufacture and how us as consumers can use little or no water in the care of our jeans.