LAUNDRY

The traditional laundry process involves hand sanding, grinding, ripping to re-create an aged appearance finished off with stone or enzyme washing several times in a giant industrial washing machine with or without bleach to determine the eventual shade of indigo.

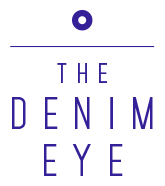

Pumice stones of varying sizes are used in the washing machine to create a worn in appearance. Instead of pumice stones we also use enzymes which are a liquidised pumice stone.

The above images demonstrate the stone washing process in a modern commercial laundry. The laundry is a significant part of the jeans making process.

Stones and chemicals are heavily used to create the vintage and used washes we love so much but they do create a large amount of waste sludge that has to be dealt with in the waste system..

Laser finishing

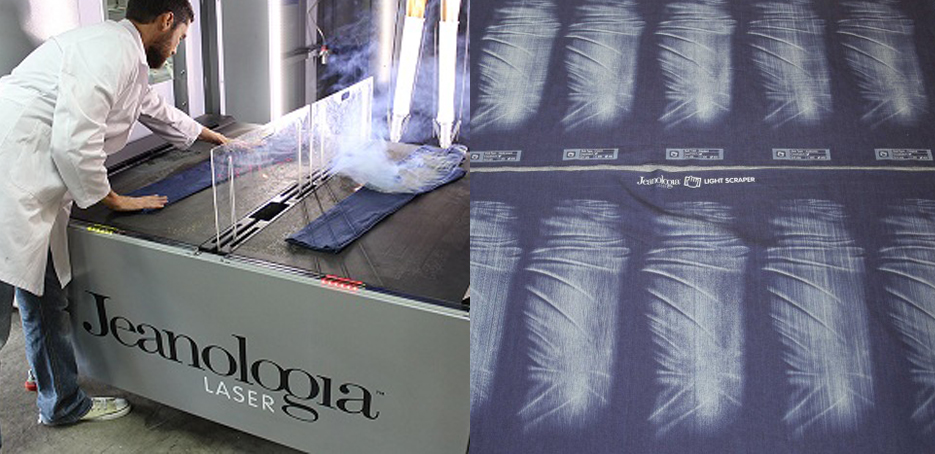

Laser finishing is a fast growing alternative to the hand degrading process.

Laser equipment can replicate such effects but the denim purists can easily tell the difference, preferring the hand and stoned effects. But this process is improving all the time. Currently Jeanologia in Spain make one of the best machines for such processes.

Sand blasting whilst good at the time was outlawed some years ago as being dangerous.

Acid wash was likewise outlawed fairly soon after it became the hottest fashion jeans finish due to the fact the dry bleached stones caused skin burns and blindness in the operatives.

Energy

Alternative sources of energy are now used to reduce what is an energy heavy industry – Solar Power; Wind energy; Water energy.

Recycle / Upcycle

Recycling

Waste management is essential in a well run denim Mill. After the spinning process all waste cotton is swept from the floor, cleaned and re-used by blending with longer fibre cotton. Garnetting equipment enables old cotton garments to be chopped up and re-spun blending with longer fibres for strength.

Upcycling for fashion.

Re-use old pieces of denim and cut up garments to make new items. This is more a handcraft based creative approach where each piece is unique. Whilst it is not a huge commercial operation for the high street it is a growing force in the jeans industry where most dedicated jeaners love the individual revival attitude.

Upcycling for the home

The Blue Jeans Go Green programme which is a trademark of Cotton Inc. repurposes old denim garments into Ultra Touch Denim Insulation. Apparently, it takes around 500-1000 pairs of jeans to insulate an average sized western home.

On a more handcraft level creative indigo rugs and accessories such as containers and organisers have reached an almost commercial level of “unique” pieces. Being sold in creative high street stores.