Originally denim jeans were made from 100% cotton and in spite of jeans now containing other fibres the main component is still cotton.

After the cotton processes, the cotton is then spun on an open end or a ring frame. The latter creating a superior quality yarn.

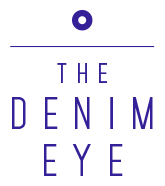

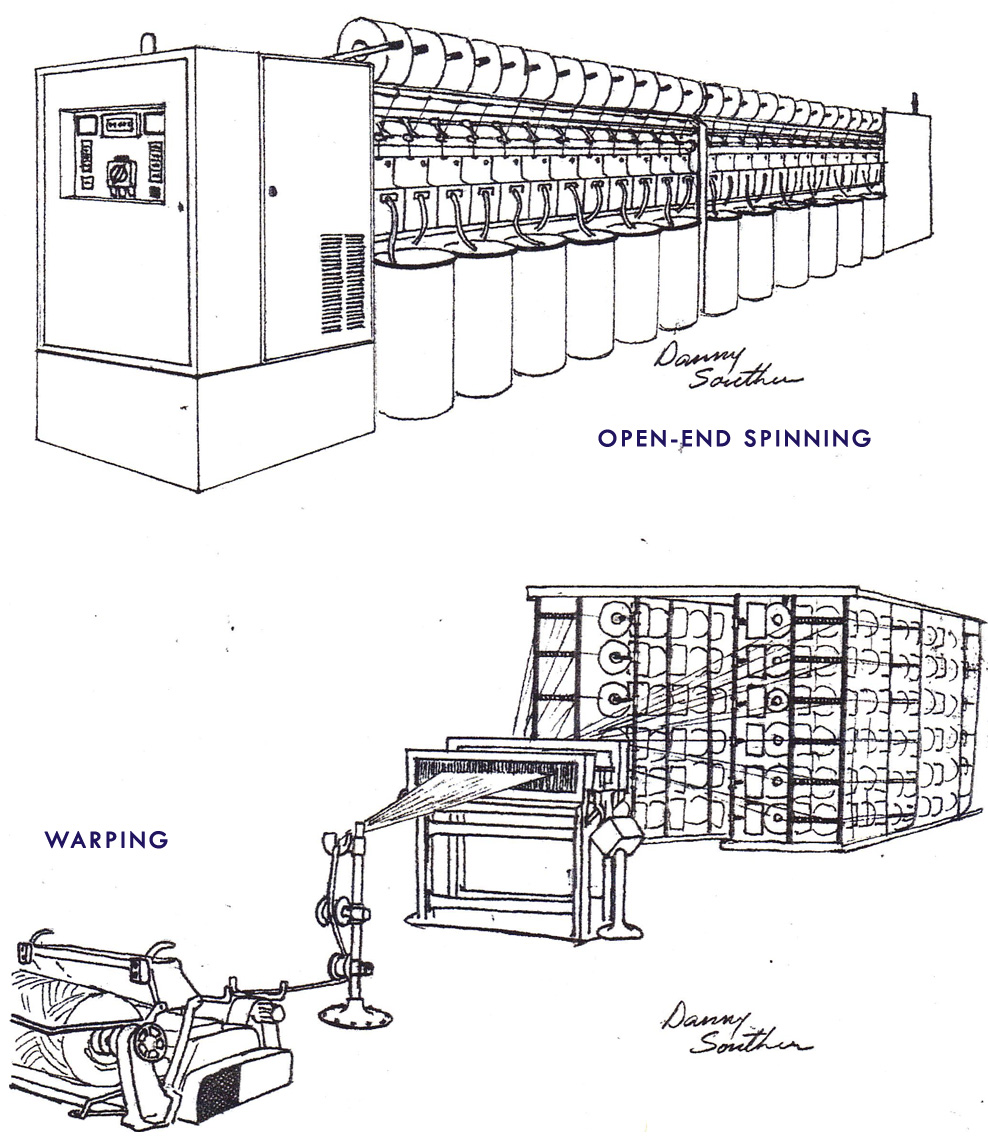

These little drawings give a birds eye view of the spinning and warping processes which are magnified in the photographs.

The above drawing depicts an open end spinning frame whilst the photograph shows a modern ring spinning frame capable of producing thousand of spindles per day. A small denim plant can manufacture around 20 million yards of denim per annum and a big plant up to 120 million. Therefore such mass cotton spinning is very much required for today's mass manufacturing requirement.

Over the coming weeks we will share some of the old denim making processes which were much more of a craft than those of today.

Workers in Pakistan going home after a day in the factories. A colourful local scene in Lahore.

Cotton and denim is delivered in heavily decorated trucks in Pakistan. Each driver takes great pride in his truck paying artisans to personalise the truck under his watchful eye.