Making modern denim fabric is a highly technical and mechanised affair.

The looms are either Rapier looms which are more slow but capable of making great developments. For speed in production air jet looms are the choice of most Mills. they are less flexible than the rapiers but super fast.

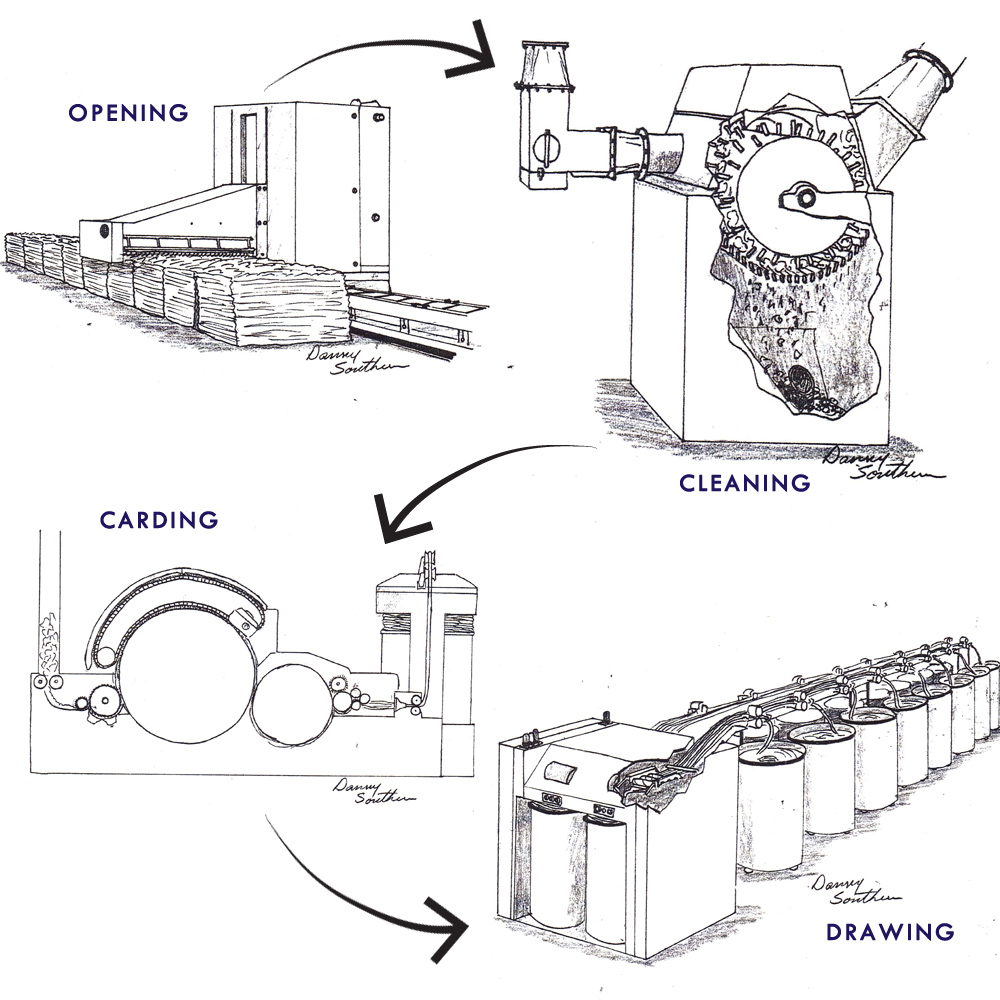

these charming drawings from Danny Southern pictures the processes from weaving through finishing and sanforizing to the final quality inspection.

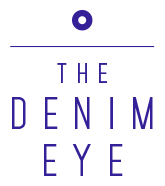

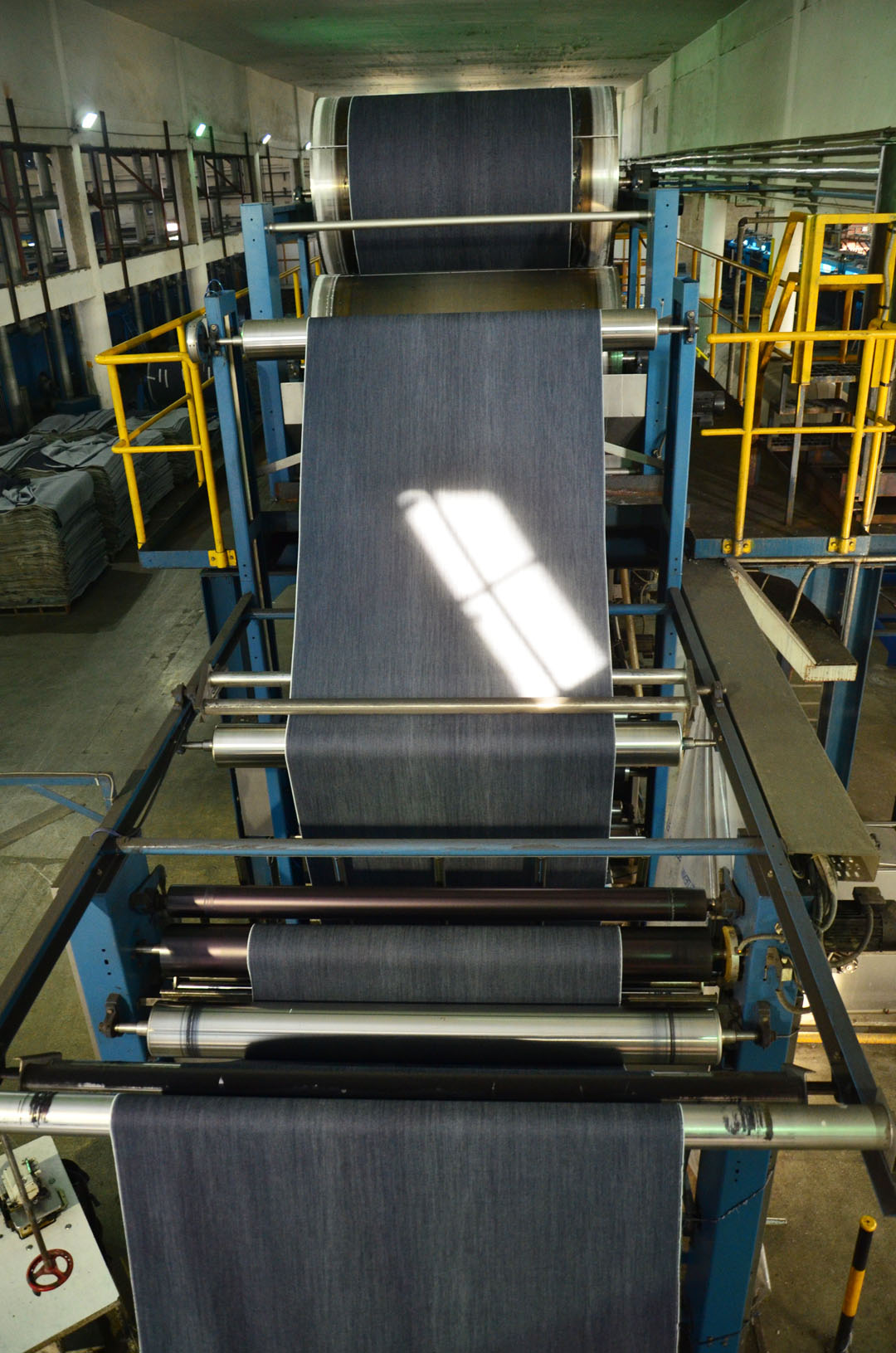

The weaving shed, finishing ranges and inspection in a modern denim factory today.